Introduction

In recent years, industrial and manufacturing sectors have witnessed significant technological advancements, including innovations in automation, material movement, and energy efficiency. One such game-changing advancement is tribupneu—an emerging term in pneumatic systems that has started gaining attention for its unique approach to tribology-enhanced pneumatics.

While not yet mainstream, Tribupneu is attracting interest among mechanical engineers, automation specialists, and industries looking to reduce friction, extend system lifespan, and improve energy conservation in pneumatic operations. But what exactly is Tribupneu, and why should professionals in air-powered machinery or fluid systems care?

In this guide, we’ll unpack everything you need to know—from what makes Tribupneu distinctive to its mechanisms, advantages, real-world applications, and future potential. Whether you work in manufacturing, automation, or mechanical design, understanding Tribupneu could future-proof your operations and give you a competitive edge.

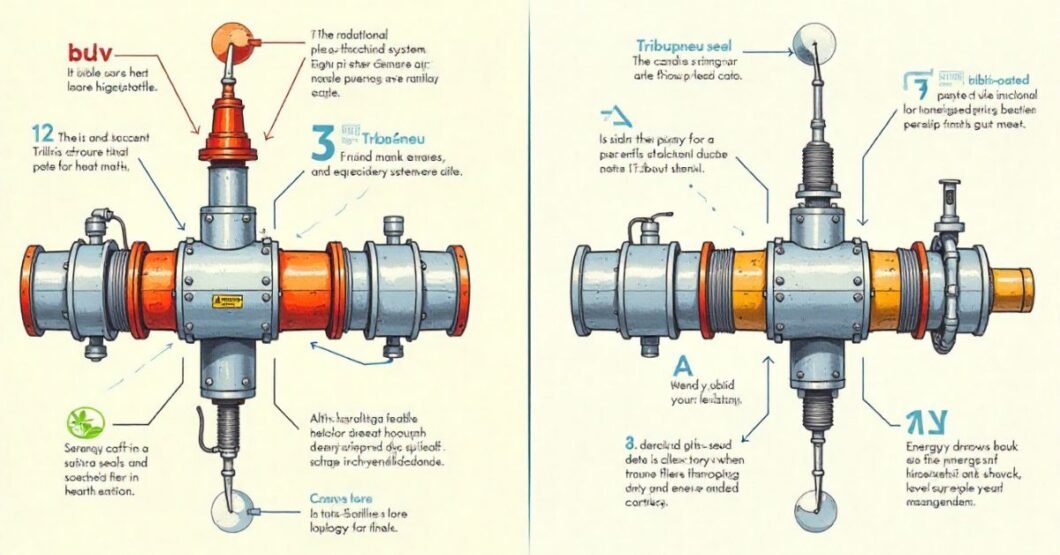

What is Tribupneu? Definition & Overview

Tribupneu is a hybrid concept blending tribology (the science of friction, lubrication, and wear) and pneumatics (systems powered by compressed air or gas). The term refers to advanced pneumatic systems optimised for friction reduction and wear management through tribological principles.

Unlike conventional pneumatic setups, which often suffer from energy loss, wear-and-tear, and inefficiency due to frictional forces, Tribupneu systems incorporate materials, coatings, and design modifications that significantly reduce these issues.

Primary Characteristics:

- Enhanced wear resistance via tribological coatings

- Higher energy efficiency due to reduced friction

- Extended lifecycle for seals, cylinders, and valves

- Lower maintenance and operational costs

This fusion of pneumatic dynamics and tribological engineering opens doors to smarter, more durable, and more efficient systems for a wide array of industrial uses.

Did You Know?

According to the National Tribology Council, friction-related losses consume around 23% of the world’s total energy production (2022 study). Technologies like Tribupneu aim to reduce that dramatically.

How Does Tribupneu Work?

At its core, Tribupneu integrates low-friction materials, engineered surfaces, and modern lubrication strategies into pneumatic systems. These enhancements are not limited to one component—they span the entire circuit, from actuators to tubing.

Design Mechanisms:

- Self-lubricating Materials: Cylinder linings and piston seals are made of advanced polymers like PTFE composites.

- Dry Lubrication Films: Tribological films minimise metal-to-metal contact.

- Surface Engineering: Surfaces are micro-textured or coated to reduce abrasion.

Process Flow:

- Compressed air input

- Friction-optimised actuator movement

- Real-time wear adjustments via adaptive valves

- Smooth force output with reduced energy loss

Expert Insight:

Dr Emma Rowley, a tribology specialist at the University of Sheffield, emphasises:

“Tribupneu is not just a materials upgrade but a systemic redesign of pneumatic ideologies. It’s about maximising output and longevity, not just movement.”

The Role of Tribology in Pneumatic Systems

To truly understand Tribupneu, we must look at how tribology transforms pneumatic operations fundamentally.

Tribology deals with:

- Friction analysis

- Lubricant performance

- Material compatibility

- Wear mechanics

Industrial Relevance:

| Factor | Traditional Pneumatics | Tribupneu-Enhanced Systems |

| Friction Loss | High | Reduced by over 60% |

| Seal Degradation | Frequent replacements | Extended lifecycle (2–3x) |

| Energy Consumption | Inefficient (10–15% loss) | Optimized use (up to 30% savings) |

| Maintenance | Monthly | Quarterly or bi-annually |

Key Components of a Tribupneu System

A Tribupneu system is not a full replacement of pneumatic infrastructure—it’s an augmentation using engineered materials and smart integration strategies.

Core Components:

- Tribologically optimised cylinders

Reduce surface drag during motion cycles. - High-durability Seals & Rings

Made from fluoropolymer mixes for lower distortion. - Polished Internal Tubing

Allows smoother airflow and less turbulence. - Adaptive Valves

Adjust pressure and flow based on in-system resistance.

Component Optimisation Table

| Component | Material Enhancement | Functional Benefit |

| Piston seal | PTFE-carbon composite | Lower static/dynamic friction |

| Valve seat | Nitrided steel surface | Wear resistance |

| Tubing interior | Nanocoated polymer lining | Anti-corrosion & lower drag |

Benefits of Tribupneu in Industrial Automation

Adopting Tribupneu can have immediate impacts on automation and machinery performance, especially in repetitive-action settings where wear and cycle frequency are critical.

Key Advantages:

- Reduced Unplanned Downtime

With better components, failure frequency drops. - Noise Reduction

Smoother surfaces and less vibration reduce system noise. - Greater Process Control

Adaptive pressure adjustment enables higher feedback accuracy.

Real-World Stats:

A 2023 case study by PneuMatech showed that switching to Tribupneu components reduced a mid-sized plant’s cylinder failures by 47% over a 12-month period.

Use Cases and Applications Across Industries

Tribupneu isn’t limited to one niche—it benefits multiple verticals that rely on pneumatic technologies.

Industries Adopting Tribupneu:

- Manufacturing & Assembly Lines

- Automotive Production

- Food & Beverage Packaging

- Pharmaceutical Automation

- Material Handling & Robotics

Sample Application Map

| Industry | Application | Tribupneu Advantage |

| Pharma | Tablet packing automation | Precision + zero oil contamination |

| Electric Vehicle (EV) | Battery housing assemblies | Non-stick movement under stress |

| Aerospace | Lightweight material testing rigs | Low wear in micro-movements |

Comparison: Tribupneu vs Traditional Pneumatics

Below is a side-by-side comparison outlining how Tribupneu stacks up against conventional pneumatic systems.

System Comparison Table

| Feature/Metric | Traditional Pneumatics | Tribupneu Systems |

| Friction Coefficient | 0.2–0.3 | 0.05–0.1 |

| Maintenance Interval | Monthly | Quarterly or longer |

| Component Lifecycle (hours) | ~5,000 | 10,000+ |

| Lubrication Requirement | Frequent | Minimal/none |

| Energy Efficiency | Moderate | High |

Market Trends and Emerging Innovations (2024–2025)

The past two years have seen several exciting developments that suggest Tribupneu will grow beyond theory.

Recent Trends:

- AI in Pneumatic Control Systems

Smart analytics are predicting wear via data patterns. - Green Manufacturing Push

Europe’s 2024 eco-regulations have industrial plants seeking low-energy alternatives. - Miniaturisation

Micro tribopneumatic systems for medical devices and semicon industries are gaining traction.

Source: European Commission’s EcoDesign Consultation Report, 2024

Implementation Challenges and Considerations

Despite its promising capabilities, Tribupneu is not without challenges.

Common Barriers:

- Higher Initial Cost

Engineered materials and coatings raise upfront investment. - Lack of Mainstream Supplier Access

Still limited to niche manufacturers or custom orders. - Learning Curve

Maintenance teams must be retrained on material-specific handling.

Tips for Adoption:

- Start with retrofit components in high-wear systems.

- Use ROI models—often, payback occurs in under 12 months.

- Partner with OEMs offering tribology expertise.

Future Outlook: Is Tribupneu Here to Stay?

In our analysis, Tribupneu is not a passing trend—it aligns with the industry’s shift toward long-term efficiency and sustainability. As energy prices rise and automation becomes more nuanced, friction and performance loss will no longer be tolerable.

Expert Forecast:

According to MarketsandMarkets, the smart pneumatics market is expected to grow from $3.2 billion in 2023 to $5.48 billion by 2028, with tribology-driven systems as a key segment.

FAQs

What is Tribupneu in simple terms?

It’s a friction-optimised pneumatic system using special materials to operate longer and more efficiently.

Is Tribupneu suitable for dirty environments?

Yes, particularly due to its low-maintenance and dry-lubed design.

Can Tribupneu be retrofitted into old systems?

Selected components like seals and cylinders can be upgraded easily.

How much can I save by switching to Tribupneu?

Savings vary, but reduced downtime alone can yield 20–30% cost benefits annually.

Are Tribupneu parts standardised?

Not yet. Many are custom-made, but standardisation is increasing.

Conclusion

Tribupneu is quietly revolutionising pneumatic system design by addressing one of the oldest mechanical enemies: friction. By applying tribological science to air-powered mechanics, it offers longevity, efficiency, and performance previously thought unattainable. As energy efficiency and reliability continue to dominate industrial priorities, Tribupneu stands out as a viable and superior solution worth exploring.

Now’s the time to future-proof your pneumatic systems. Consider evaluating a pilot upgrade, running diagnostics on high-wear areas, or consulting with a pneumatic specialist to see how Tribupneu fits into your operations.